IMPORTANCE OF PROPER GRINDER MAINTENANCE:

The more common cause of wheel breakage has been traced to improper speeds,abusive operation and/or careless handling of the grinder.Therefore proper and regular maintenance,service,and inspection procedures are of great importance in preventing wheel breakages.Regular inspection and maintenace procedures are the responsibility of the user.All portable type grinders,chop saws,and cut off saws(corded,cordless,or gas powered) should be inspected at regular intervals to insure that the mounting flanges are in good condition,proper size and shape,that the speed governing device is functioning properly,and that no damage has occurred to the tool or wheel as a result of abusive use or careless handling,Comply with safety requirement in ANSI B7.1,ANSI B7.5 and OSHA REGS 29CFR 1910.215 and 1926.303

The following Do’s and Dont’s should be used as a guide to safer portable grinding and cutting:

MUST DO

1.DO always handle and store wheels in a careful manner

2.DO make sure grinder speed does NOT exceed maximum operating speed markedd on the wheel,its blotter or container

3.DO visually inspect all wheels before mounting for cracks or other damage.Do NOT use if present.

4.DO use mounting blotter when supplied with wheels

5.DO be sure wheel hole,threaded or unthreaded,fits the grinder spindle or pilot diameter on backing flange properly and that flanges are clean,flat,undamaged and are the proper type for the wheel you are mounting.

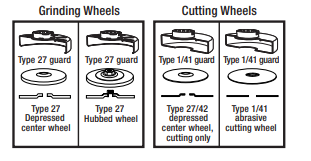

6.DO always use proper guard.Position it so it protects the user.

7.DO allow newly mounted wheels to run at maximum grinder speed in a protected area,with guard in place,for at least one minute before using.

8.DO always wear eye protection ANSI Z87.1 and a face shield,if required.

9.DO always wear hearing protection ANSI S12.6.

10.DO always wear additional safety clothing such as gloves,apron and boots.

11.DO always secure the workpiece firmly while it is being cut or ground.

12.DO always be aure tool is disconnnected from power supply or battery and switch is in “OFF” position before changing wheel or adjusting guard.

13.DO employ dust controls and protective measures appropriate to material being ground.

14.DO comply with OSHA regulations 29 CFR 1926.1153 when working on materials containing crystalline silica such as concrete,mortar and stone.Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure.

15.DO Hold grinder firmly with two hands per the grinder instruction manual.Maintain firm grip.

DON’T

1.DON’T use a wheel that is past its expiration (EXP) date as marked near center of wheel,if provided

2.DON’T use a cracked wheel or one that has been dropped or become damaged

3.DON’T force a wheel onto a grinder a alter the size of the mounting hole,get one that fits.

4.DON’T ever exceed maximum operating speed of wheel.

5.DON’T use mounting flanges on which the bearing surfaces are not clean,flat and free of burrs.

6.DON’T overtighten nut or flange,tighten only enough to hold wheel firmly.

7.DON’T grind on the side of conventional straight or Type 1/41 wheels

8.DON’T use a wheel on any grinder that is not proper designed for the specific application of the wheel.

9.DON’T start the grinder until the wheel guard is properly and securely in place.

10.DON’T jam wheel into the work.

11.DON’T stand direcly in front of a grinding/cutting wheel whenever a grinder is in operation.

12.DON’T grind or cut material for which the wheel is not designed for.

13.DON’T use grinding or cutting wheels on pistol grip air sanders.

14.DON’T use mount more that one wheel on a grinder.

Whatsapp

Whatsapp